Digital Customized Implants

At Asaad Factory, we combine cutting-edge 3D imaging, and surgical expertise to create patient-specific implants

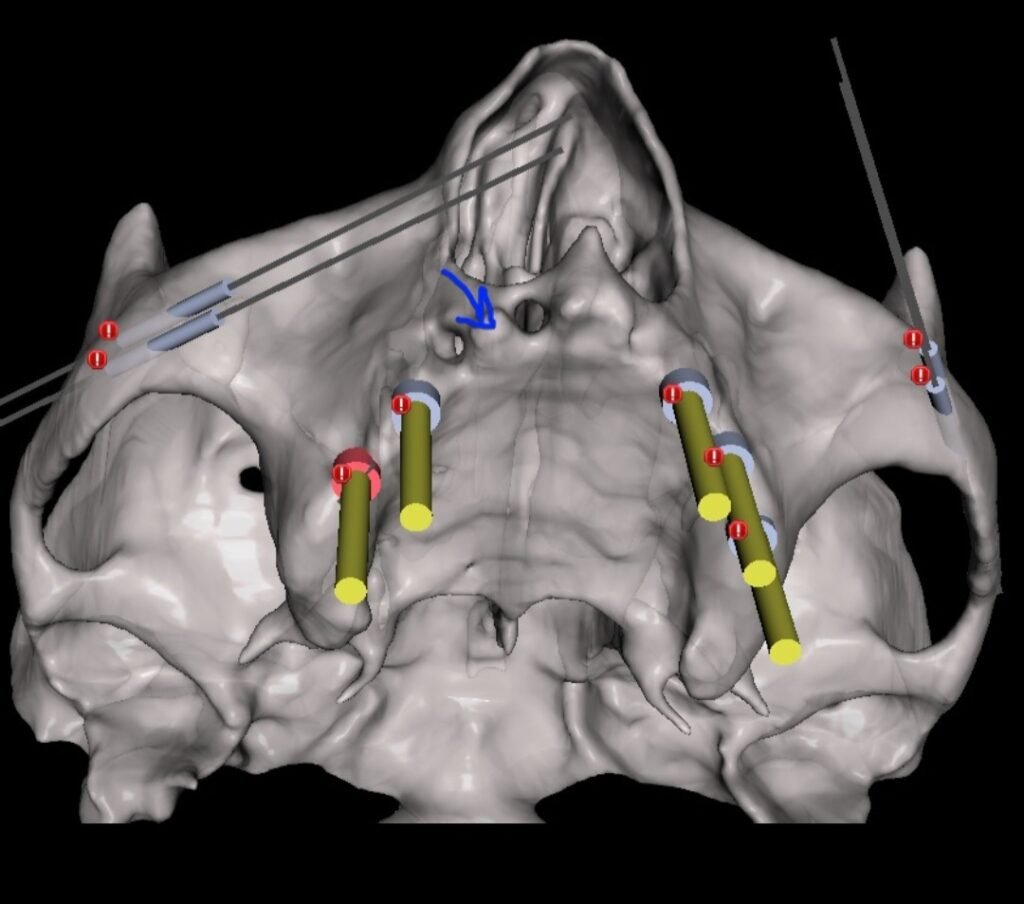

Design Process for Subperiosteal Implants with Parallel Abutments

Step 1: Patient Assessment & 3D Imaging

CBCT Scan (Cone Beam Computed Tomography):

High-resolution (<0.2mm voxel) scan of the atrophic jaw.

Must include full arch (edentulous area + 10mm beyond).

Soft Tissue Evaluation:

Assess mucosal thickness at proposed abutment sites (≥2mm ideal).

Step 2: Digital Bone Mapping

3D Model Reconstruction:

Convert DICOM files to STL using software (e.g., Materialise Mimics).

Isolate bone morphology, excluding nerves/vessels (Safety Zone: 2mm from inferior alveolar nerve).

Virtual Osteotomy Planning:

Mark bone support zones (minimum 4mm width for primary struts).

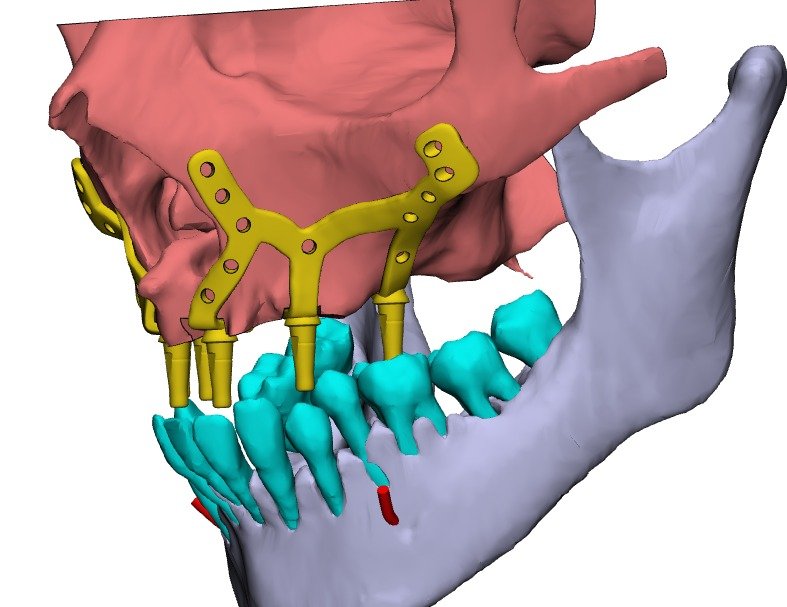

Abutment Engineering

Step 3: Framework Design

Primary Structure:

Design titanium mesh framework following bone contours (0.6–1.0mm thickness).

Incorporate:

Load-bearing struts along the mandibular body/maxillary buttress.

Retention fins (0.3mm) for soft tissue stabilization.

Abutment Planning:

Place 4–6 abutments per arch in prosthetically driven positions:

Canine & first molar regions (mandible).

Lateral incisor & premolar regions (maxilla).

Parallelism Requirement:

All abutments aligned within 5° divergence

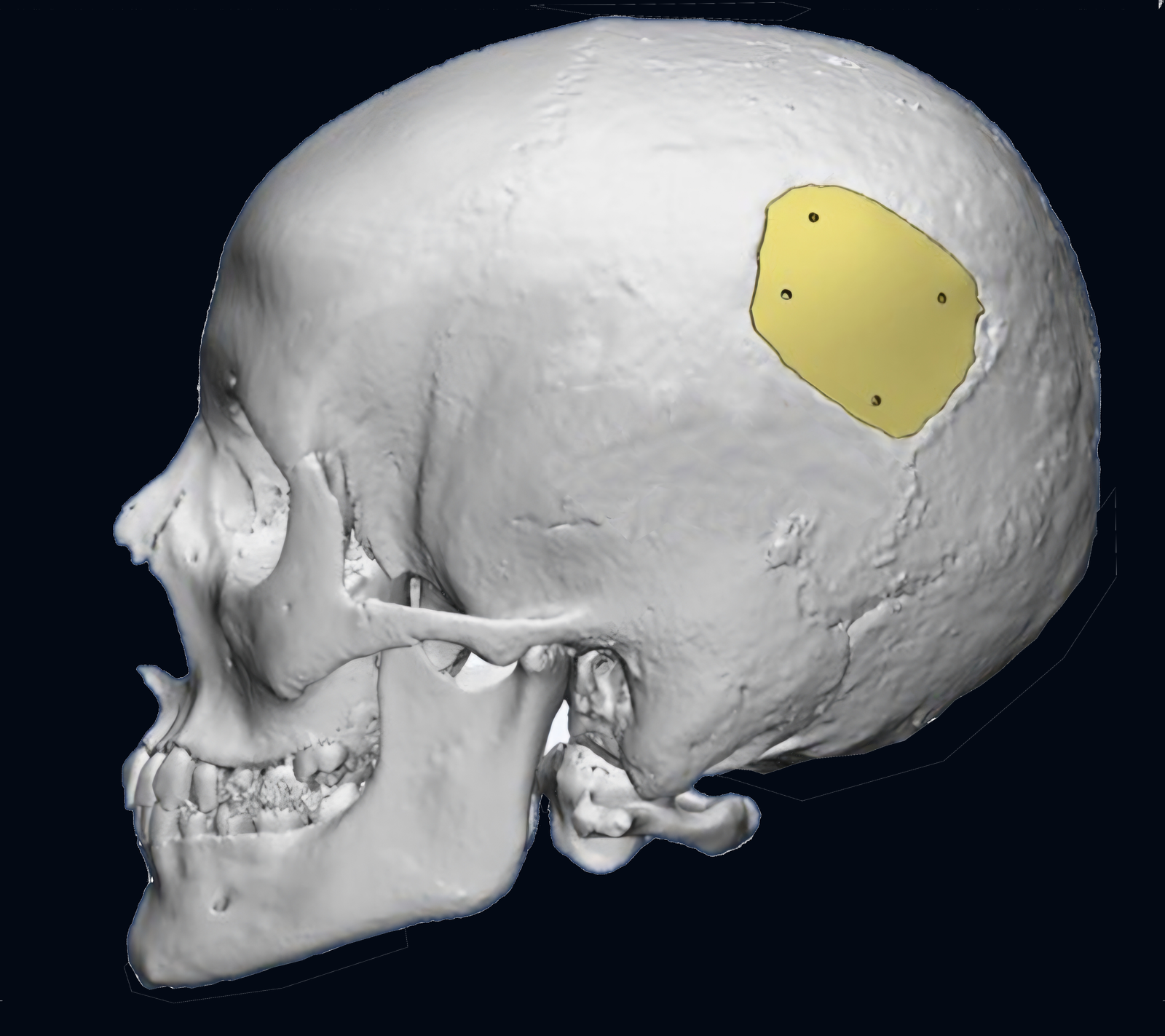

Precision-Crafted PEEK Implants – Customized for Perfect Fit & Performance

Why Choose Custom PEEK Implants?

At Asaad Factory, we combine cutting-edge 3D imaging, advanced PEEK manufacturing, and surgical expertise to create patient-specific implants that restore both form and function. Designed for cranial, maxillofacial, and orthopedic reconstructions, our custom PEEK implants offer unmatched biocompatibility, durability, and anatomical accuracy—tailored to each patient’s unique needs.

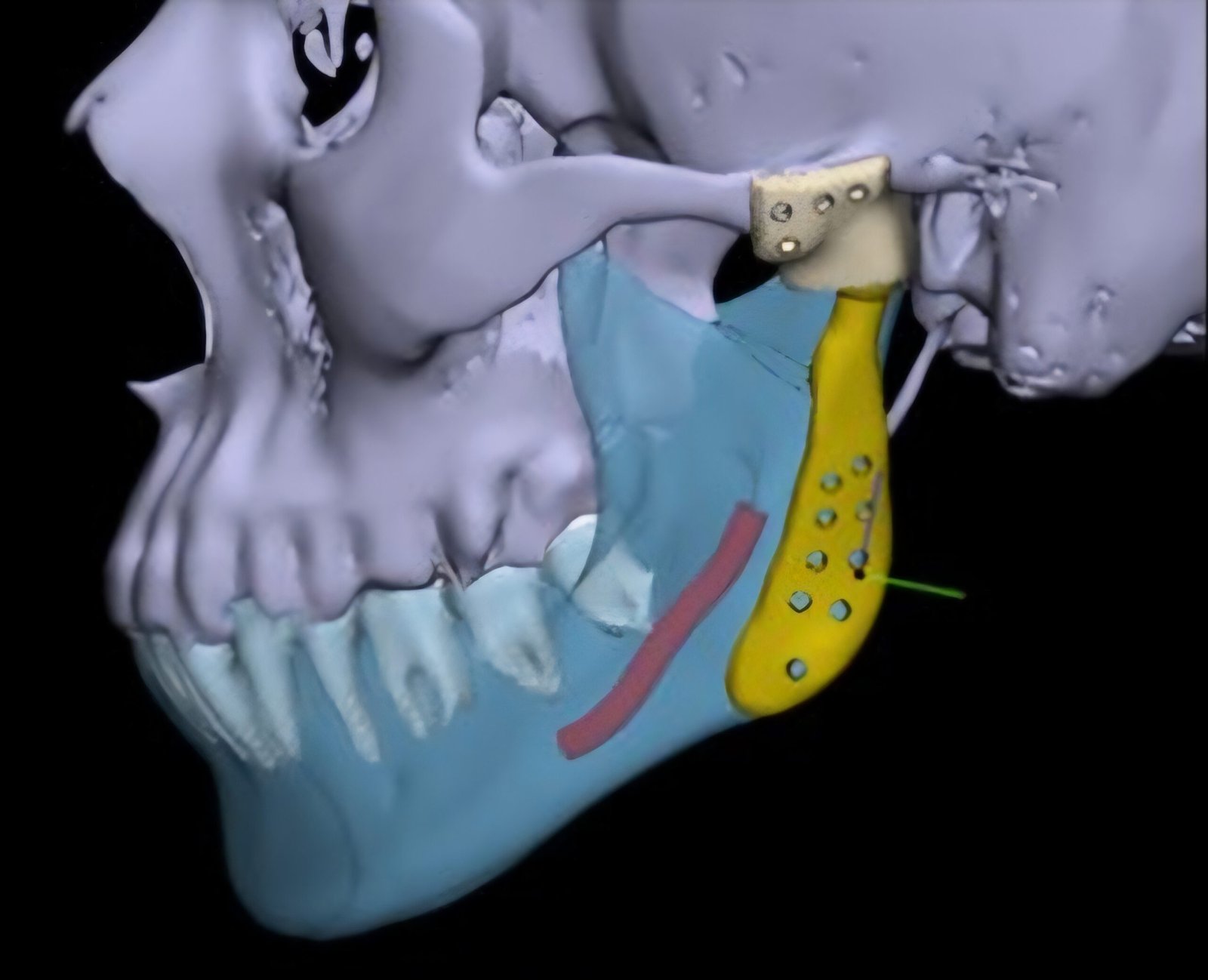

Why Choose Asaad Factory’s Custom TMJ Prostheses?

✔ Fully Personalized Design – Tailored from CBCT scans for perfect anatomical alignment.

✔ Medical-Grade Titanium (Ti-6Al-4V ELI) – Biocompatible, corrosion-resistant, and long-lasting.

✔ Precision CNC Machining – 10-axis CNC technology ensures micron-level accuracy.

✔ Faster Recovery – Engineered to replicate natural joint kinematics, reducing post-op complications.

✔ Local Saudi Manufacturing – ISO 13485-certified production with rapid GCC delivery